Category: Under $50 Million in Annual Revenue

Front row (l-r): Kent Anderson (owner/office manager), Howard Hopper (retired owner/manager), John Hopper (owner/manager), Samantha Quinn (information manager); back row (l-r) Rod Thompson (parts manager), Marlin Brenden (service manager), Jim Gergen (service manager), Joe Janisch (parts assistant manager).

Founded: 1929 (Acquired by Howard Hopper in 1962.)

Major Line: John Deere Ag, Turf and CWP

Shortlines: Fast Sprayer, Unverferth, MDS

Locations: 1 – Watertown, S.D.

Employees: 39

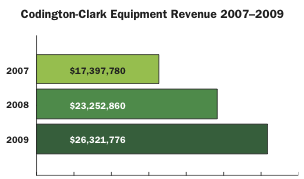

2009 Sales: $26,321,776 (Wholegoods $19,502,583; Parts $4,644,880; Service $2,174,314)

2009 ROA: $26.84%

2009 Market Share: 47.2%

2009 Parts/Service Absorption Rate: 115.02% (Parts 65.58%, Service 49.44%)

Customer Satisfaction Index: 95%

Awards: Farm Equipment’s 2009 “Best-in-Class” Dealership

John Hopper remembers attending an implement dealers’ conference 10 or 15 years ago, and one of the talks he sat in on was called, “How to Make Your Business Bulletproof.”

For 2 hours the speaker hammered home the point that parts and service is the backbone of an equipment dealership’s business. “I remember that he said if you can achieve an absorption rate of over 100%, you’ll always be in business,” Hopper says.

When the speaker asked who in the audience had an absorption rate over 100%, Hopper says that only one person raised their hand. “I know I didn’t raise my hand, but I left that meeting thinking, ‘That makes a lot of sense.’ Wholegood margins are always difficult. There are so many highs and lows, peaks and valleys in this business for wholegood sales. If we’re going to grow our business, we needed something to stand on. So that’s what we did.”

What Hopper and his partners at Codington-Clark Equipment in Watertown, S.D., did was to grow their John Deere farm equipment business by focusing on customer satisfaction. The dealership’s 95% customer satisfaction index in 2009, he says, is firmly centered on offering outstanding parts and service business. At the heart of meeting and exceeding customer expectations are the people providing the service, Hopper says. “It took us a long time to do it, but we put the right people in management positions, and they make the difference.”

It’s that “difference” that led to Codington-Clark Equipment’s selection as Farm Equipment’s 2010 Dealership of the Year in the $50 million and under annual revenue category. The dealership was also among the two Best-in-Class dealerships in 2009.

By Any Metric

Measured by nearly any business metric, this single-store dealership can hold its own against even the biggest ag machinery dealers in North America.

At $674,917 in revenue generated per employee, Codington-Clark ranked highest of all the nominees in their category. It may have been even higher if only the full-time staff were counted, as some of the dealership’s 39 employees are part timers.

They also had the second highest return on assets in the group at 26.81%. The dealership achieved a 95% rating in John Deere’s customer satisfaction index for 2009. But what really impressed the judges who made this year’s selections is Codington-Clark Equipment’s 115% parts/service absorption rate. No dealership, including those in the over $50 million revenue class this year, came close to challenging Codington-Clark in this category.

Since John Hopper joined the dealership in 1981, he’s tried to follow the example set by his father, Howard Hopper, who acquired Codington-Clark in 1962. “Ever since I was a kid, dad has told me time and again, ‘You always have to be in the top half. And when it gets down to just two of you, you’d better be really good.’ That helps guide us in everything we do.”

‘The Way We Do It’

John Hopper knows that not everyone shares his view of how to stay in the “top half.” He believes that if Codington-Clark is going to be viable 5 years from now it needs to stay on the cutting edge.

“We need to stay ahead of the pack. It’s going to take a solid core group of people who can do two things. One is they can satisfy customers and keep them coming back. The other is the people around them learn by their example. That’s exactly the way this business works for us,” he says.

Hopper adds that it’s not a numbers thing when he talks about performance. The ownership doesn’t “pull the reins in on people” when they want to do things to help improve their position in the store.

“We don’t say, ‘You have $750,000 for parts inventory.’ Our position is if you need it and you think you can sell it, let’s stock it. That’s the way we do business. It’s a luxury of being a single store,” Hopper says.

“It’s a luxury of the owner/manager being here and seeing what happens in the dealership day in and day out. And it’s the way we prefer to operate. It may or may not be the way others do it, but it’s the way we do it.”

Hopper describes their management style as build it and they will come. “We’ve had times in our history when we had the wrong people in the wrong positions and we saw first hand the impact that can have on our business.”

Codington-Clark’s young staff “has re-energized the sales department,” says John Hopper. “With the higher sales of new equipment, we’ve got more used goods than we used to have,” he says, pointing to the line up of used combines at the front of his lot.

Building on the Backbone

Whether or not it’s how others choose to run their business, Hopper and his partners took to heart the message that parts and service are the backbone of their business. And since that time 10 or 15 years, they’ve built their long-term vision around it.

In fact, this single-store dealership’s parts department won Deere’s Century Club award for parts volume. It’s an award that recognizes its top 50 dealerships in parts sales in North America.

“It’s unfortunate, but they changed the rules this year. Instead of total sales per dealership, it’s awarded based on sales per ownership group. It’s OK, but I feel bad because it was a testament to what our guys get done around here. They do a lot.”

Unless something goes wrong, Hopper says the dealership will sell $5 million in parts this year. “For a single store, that’s a big deal. We’re one of the very first John Deere stores to have bought or sold a million dollars worth of parts in a year.”

But John Hopper says there are a lot of different answers to how they’ve maintained a 100-plus absorption rate, but it all gets back to having the right people in the right place.

“If you asked any of our customers if our parts or service managers know what they’re talking about, there’s no doubt that they’ll tell you ‘yes.’ They’ve developed the expertise and established trust and confidence with our customers. That’s what draws business here,” Hopper says.

The payoff has come not only in their customers making Codington-Clark their first choice when it comes to parts and service, but they’ve also managed to build service work from customers who purchased equipment from other dealerships.

According to Howard Hopper, Codington-Clark handles more than 100 combine and 80 tractor service inspections a year. “We’re seeing more and more stickers from other dealerships on that equipment,” he says. “And they seem to be coming from farther away.”

Those stickers represent some of the biggest and best dealerships in the region, says John Hopper. “They’re good dealerships. It’s just that people like what we do for them. Our service sells itself, and we believe it’s because we have the right people in the right position. Customers like our folks and trust them and that’s what it’s all about.”

While 4-wheel-drive tractors and combines are at the heart of Codington-Clark Equipment’s increased sales in recent years, the dealership also maintains a complete inventory of turf and law equipment to appeal to its rural lifestyle customer base.

It’s not unusual for a farmer to spend between $5,000 and $10,000 to have Codington-Clark inspect their combines and get them ready for harvest. During the first week of June, 14 combines could be counted in the dealership’s service areas.

In 2008, the dealership added 12,500 square feet of service space taking the total service area under roof to 72,500 square feet.

“Our combine shop can hold 16 combines with space to work on every one of them. And we get them all year round,” Howard Hopper says. “Tractors were a little slower in coming, but now we’re working on them all year, too.

“We do the little things that customers like. As part of the inspection we clean the cab. We wash it down, and when the customer picks it up, it looks as good as the used ones we sell on our lot. They’re pretty proud of that old combine when they take her home. Every dealership hears that what they do always costs too much money. We don’t hear that on our service inspections because they like what they see.”

John Hopper says, “Their equipment is worth more in trade in if it’s been through our shop every year. They get some of it back later on and that makes a big difference, too.”

While the dealership is doing more service work from customers who are farther away, John Hopper says their goal is not to spread out so much that it affects the quality of the service. “Our goal is to take care of our AOR and get every piece of business that’s in it. I’m not going to tell you we’re hauling combines in here from other dealer’s AORs, but we’re getting more and more of the lion’s share of what’s here.”

What the Judges Say About Codington-Clark

“Achieved the highest dollars generated per employee among nominees in this category” … “Had the second-highest ROA at 26.81%, which is ‘very’ good” … “What really impressed us was their high absorption rate of 115%” … “Their CSI was 95% on Deere’s program” … “Had a very good asset turnover ratio at 3.19% and solid market share” … “Three-year growth was always in the high double digits”

Return on Sales

While the owners of Codington-Clark obviously track return on assets, John Hopper says they prefer to keep track of their return on sales. ROA, he says, is the product of return on sales (ROS) and asset turnover.

“In our opinion, ROS measures a dealership’s ability to make a profit, grow the business, train employees, expand into new profit centers and satisfy your customer’s growing expectations. When you can maintain ROS and asset turnover, your business is hitting on all cylinders,” Hopper says.

He explains that net operating return on assets is the result of two other factors — profit margin and asset turns. “If you have the ability to make a good margin and do it often, it’s a lot better than just return on assets, because it multiplies. That’s really what helps you build ROA.”

Sustainable Market Share

Talking market share can be a sensitive area for many farm equipment dealers because of the focus it often places on sales volume and other factors that can affect profitability, new and used wholegood inventories, inventory turns and in-field inventory.

“We set our internal market share goals at 50%,” John Hopper says. “It’s our experience that there is a balance point for market share needed to maintain long-term wholegoods sustainability. He says to get to 60-65% will cost him margin. “That’s all there is to it. You have to decide if it’s worth it or not.” He wouldn’t be surprised if the dealership soon makes it to 60 or 65% market share.

“We’ve done a really good job on 4-wheel drive tractors and combines,” says John Hopper. “If we make it, great, I’m not going to say we won’t take those deals. But inherent with that is the fact that we’ve taken a lot more risk.”

Pointing to a long row of used combines at the front of the Codington-Clark lot, John Hopper says, “We’ve got quite a few used combines lined up there, and the new ones aren’t here yet. All of that equipment needs to have a new home by harvest time.”

With the high level of combine sales over the past few years, moving trade-ins has become a major challenge for a lot of dealers. John Hopper says their dealership has three options for turning their trades. “Our first choice is to recondition them and get them out on the lot because that also sells parts and service. It helps sell more machines. How you get an absorption of 120% is to work the system.”

Equipment that’s not worth the dealership’s time or investment either goes to a downstate wholesaler or to a dealer in Mexico that bought four or five combines from Codington-Clark a few years ago. “I’m cautious and I’m conservative. We e-mail him pictures of the equipment, and he wires us the money. His truck shows up, we help him load and away it goes,” Hopper says. “But until we move that trade, we haven’t really made any money. We just bought some iron.”

Codington-Clark has taken full advantage of the strong agriculture equipment

business during the past few years, growing its total sales by 23% in 2007, 34% in

2008 and 13% in 2009.

Re-Energizing the Business

Another thing that John and Howard believe they’re doing right is to keep fresh blood flowing throughout the organization. For example, in 2007 when one of the partners, who was also one of the dealership’s three salesmen, retired, John Hopper and his partners decided to rebuild the sales department.

“A few months before my partner retired, we took a young guy from parts and put him in sales. Then we moved one of our young service techs to sales, and hired another young man from outside the dealership. It re-energized the sales department, and when you see the numbers that we’re doing, you have to give them a lot of credit. They’re young and they’re hungry. They understand the technology side of it maybe a little bit better than somebody who’s 50 years old.

“With the higher sales of new equipment, we’ve got more used goods than we used to have. But we’re also making more money.”

Getting new blood in the organization is also why they brought Samantha Quinn into the dealership. She’s Codington-Clark’s information manager and John Hopper’s daughter, who happens to have a degree in information technology.

“Where else can you find people to work on Green Star and understand all the new technology? We also have an AMS specialist, but when you can find young people to re-energize the business, that’s a big asset, and it doesn’t matter what business you’re in. It just means a lot to put the right people in the right positions,” John Hopper says. “We’re really fortunate to have the people that we have here.”

As far as finding young talent, Kent Anderson, one of John Hopper’s partners and office manager for the dealership, says “the Lake Area Technical Institute in Watertown is a huge resource for us. More than half of the people working here went to school at Lake Area Tech. Recently, they built a multi-million dollar expansion onto the school to make room for additional students in their diesel program. They have room for 60 students and already have 90 new applicants. We’ve developed a good relationship with the instructors at the school, and we support the program as much as we can. It’s just a tremendous resource for developing talent.”

No Skimping on Employee Training

For a dealer to say he believes that training is vital in keeping his workforce on the leading edge, and actually investing in it can be two entirely different matters. At Codington-Clark Equipment of Watertown, S.D., employee training is a case of actions speaking louder than words.

In 2009, the dealership attained 138% of the training goals set by John Deere, its mainline equipment supplier.

John Hopper, owner and store manager, says that with the variety of ways that training is being delivered today, there really aren’t many excuses a dealership can give as to why employees aren’t receiving the training they need.

While Codington-Clark Equipment still utilizes some classroom courses, for the most part they’re taking advantage of the distance-learning classes that are increasingly prevalent today. “Our people make use of computers and use the distance learning modules that Deere makes available. They go through the various study guides and take a test when they’re done,” Hopper explains. “And then Deere provide us with education progress reports for the dealership.”

For example, the goal for the sales department was 120 hours of training, and Codington-Clark’s sales staff reached 212 hours in 2009. “We hired some new people and they needed more training to understand the system. We also took advantage of some Dale Carnegie sales training that John Deere sponsored,” Hopper says.

As might be expected, the service area is where much of the heavy-duty training is needed. The goal for the 17-dealership people involved was 340 hours. Codington-Clark easily surpassed that, racking up 468 hours of actual training.

“Service is such an evolution,” Hopper says. “It’s like being a doctor. You went to med school 10 years ago, but the practices used today aren’t close to what you trained to do back then. You need to keep training.”

In total, the dealership’s training goal called for 580 hours. Last year, it booked 800 hours.

He says Deere is pushing even harder for tech training as they roll out their new Tier 4 engines. “I expect that we’ll spend most of our training hours just working on Interim Tier 4 technology,” Hopper says.

In addition to understanding the technology and being able to work on the new engines, he says every employee will need to be familiar with what IT4 is and require training on how to talk to customers about it.

The Future is Here

While Codington-Clark remains a single-store dealership, John Hopper knows it’s absolutely essential to stay on the cutting edge of the technology that is flooding the farm equipment business. As more customers demand it, precision ag technologies are demanding more time and attention from the dealership.

John Hopper points at Quinn and says, “That’s her job,” and she joins the conversation. “We have four RTK towers with room for one more, which cover 85-90% of our AOR. A good percentage of our customers are using some sort of precision John Deere equipment. Some are at the basic level and others have more than one RTK system. They’re really embracing the new technology. As time goes on, they see what their neighbors are doing with it, and they want it or something more. It seems that once somebody tries precision ag equipment, then exponentially more people want it.”

Codington-Clark’s 95% customer satisfaction index in 2009 has its roots in an outstanding parts and service business. That’s reflected in the 115% absorption rate it achieved in 2009.

Part of that “something more” includes taking the data collected by the farmer and making sense of it. “We started offering a service this year where we take their flash cards, unload the data for them, put their maps together and prepare their reports,” says Quinn. She expects this to be a new profit center for the dealership.

Hopper says that it would have been easy for Codington-Clark to put its head in the sand and hope that all of the advanced technology would just go away. “That would have been a huge mistake for us because our farmers need it.”

At the same time, he admits, “This wouldn’t have been easy for us without Sam. It’s vital for us as a dealership to be as ingrained in this technology as we can possibly get. It’s the future and it’s never going to go away. But it takes a whole different skill set. I can hear her diagnosing problems for customers on the phone and wonder how she knows all of this stuff. If we’re going to be successful in the future, we have to be there.”

And with more technology coming, helping farmers understand and adapt to the new precision ag equipment is a full-time job. To stay competitive, the farmer needs his equipment dealer to be on the leading edge of technology.

“The producer who can get more done in a day using technology can farm more acres or spend more time keeping up on the markets or accomplish more than one task at a time. And John Deere’s has a lot of new things already in the pipeline, like JD Link where they can communicate with equipment in the field and know what’s happening with a machine on a real-time basis. It’s dealers like us who are moving these new tools into the field,” Hopper says.

From Here to There

“We do the little things that customers like,” says Howard Hopper. “As part of the service inspection, we wash the equipment down and clean the cab. They’re pretty proud of that old combine when they take her home.”

Reflecting on where the dealership has been and where it’s going, Anderson, says, “When we got out of college in 1981, John and I came into this business bright eyed and bushy tailed, and things were looking great. We all know what happened in this business from 1981 to ’86.

“That experience made us pretty conservative, but it was probably the best education we could have gotten. Today, we make decisions based on what it will do for us in terms of productivity. We won’t make a move because it’s trendy, or because somebody else says we should do it. We sit down, analyze it and do what we think is best for us.”

He says that Codington-Clark will continue doing what has worked for them because it has worked for their customers. Especially with the onset of the new technology and their need to improve overall efficiency of their operations, Anderson believes farmers are going to need dealers more than ever.

“At the same time they don’t want to be held hostage to us or feel trapped by the new technology. And whether or not a sale is involved, we have to be the resource they turn to when they need help. If we have a good, strong parts foundation, and if we have a good strong service support system, we’ll help them and we’ll make some money.”

Even with her young eyes, Quinn sees what it takes to succeed in the farm equipment business. “We need to maintain a high level of efficiency because that affords us more time to be with the customers who need us,” she says.

In other words, Codington-Clark believes they’re headed in the right direction, which includes being a leader. “Our customers believe we’re leaders when it comes to farm equipment,” says John Hopper. “Being a leader and staying a leader is always tough and it won’t be getting any easier. That’s why we’re always looking for dynamic young people to bring up in the business. They’re our future.

“John Deere is the best product out there along with providing the best support programs for dealers. So, it’s up to us to stay on the cutting edge, and keep leading and developing people for the next 5, 10 or 15 years. It’s on our shoulders.”

No service job is too small for Codington-Clark’s service department. Keeping

lawn tractors operating at their best is as important to the homeowner as keep-

ing a farmer’s big equipment running in the field.

Post a comment

Report Abusive Comment